UV light test inside Q-SUN Xenon Arc Test Chamber

Impact Laboratories already know what the Q-SUN Xenon Arc Test Chamber does to expose test specimen to UV light and real life weathering test conditions. However, we wanted to explore what it actually looks like from inside our weathering test chamber.

We decided to use a GoPro Hero 4 Black camera and its waterproof casing to protect against the spray and moisture conditions taking place within the chamber. The GoPro camera was placed on the right-hand top corner of the tray, positioned to show the majority of the chamber and facing down towards the samples on test. The camera catches the samples on one of the two, 18-minute spray cycles where we can see them getting exposed to a lot of water, mimicking a rainstorm. Very bright UV lighting is still used within this cycle.

The UV lights reach extremely high levels of brightness, levels which the GoPro camera could not handle. Therefore, the video footage shows the amount of brightness within the machine and lines begin to appear across the screen. You are still able to just make out what is happening in the background of the chamber but the camera continues to struggle to adjust to the UV light exposure.

A member of our technical team opens the chamber at periodic intervals to evaluate the test specimen. The test samples then undergo a UV light test cycle where the humidity within the Q-SUN xenon arc test chamber machine begins to dry the samples off. The UV light test and spray cycles are repeated over a number of hours specific to the standard which the samples are being tested to.

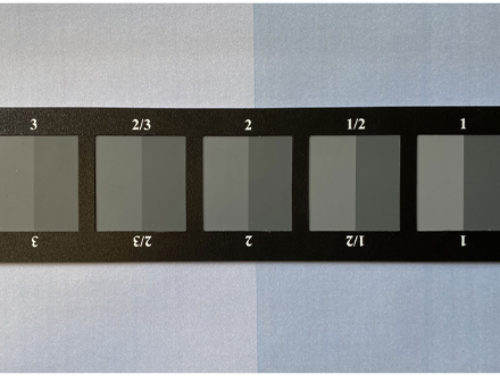

The xenon lamps produce the most realistic full spectrum of natural sunlight which enables impact to provide an accurate simulation of weathering testing, especially when testing for colour change and lightfastness. These lamps have to be changed every 1200-1500 hours. You can see one of impact’s lab technicians changing a xenon arc lamp here.

If you are interested in learning more about this test, contact a member of our team today and they can walk you through the testing process in more detail.

Be sure to also follow us on LinkedIn, Facebook and Twitter for more relevant content!