Climatic Testing vs. Accelerated Weathering Testing: Key Differences

When developing products for extreme or outdoor environments, it’s crucial to test their durability and longevity. Two fundamental methodologies used for this purpose are climatic testing and accelerated weathering testing. Although both aim to assess material resilience, they operate under different principles and conditions.

Climatic Testing involves exposing materials or products to controlled environmental conditions that mimic the actual climate they will encounter. This method evaluates how products perform under factors such as temperature and humidity over extended periods.

Accelerated Weathering Testing focuses on simulating the aging process by subjecting materials to intensified environmental stressors within a shorter timeframe. This testing uses equipment to enhance factors like UV radiation, moisture, temperature, dark cycles and condensation to predict how materials will age and perform over the long term.

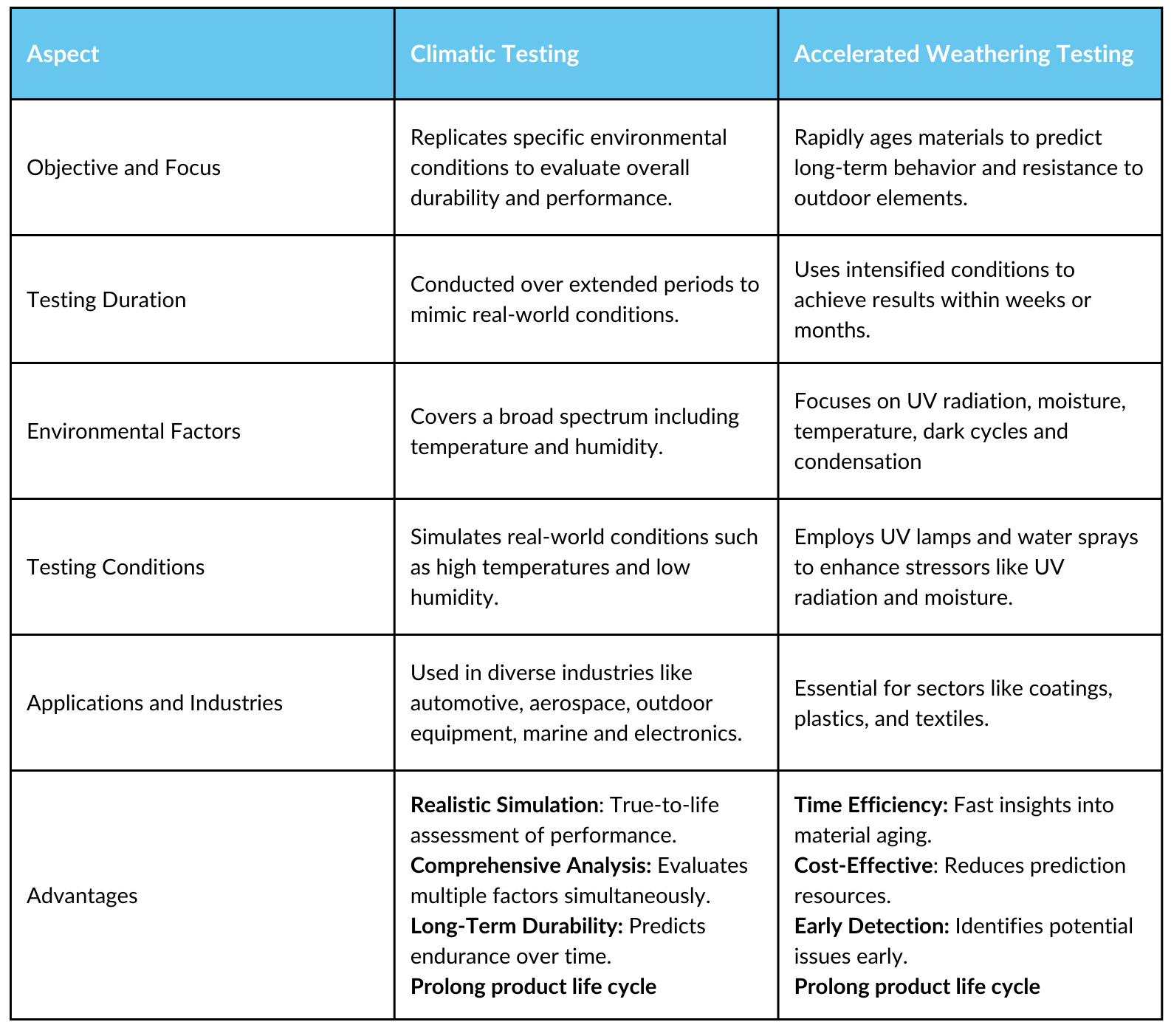

The table below highlights the key differences between climatic testing and accelerated weathering testing:

By understanding these differences, manufacturers can select the appropriate testing approach to ensure their products are both robust and reliable in their intended environments.

Ready to learn about your product durability? Contact us today to learn more about how climatic and accelerated weathering testing can provide valuable insights and help you develop more durable and dependable products. Get in touch to discuss your specific needs and how we can assist you.