Thermal Analysis in Plastics: Thermogravimetric Analysis, TGA

Plastics and polymer-based materials have become increasingly popular over the last years and because of their excellent mechanical performance, physical/thermal properties and light weight characteristics they continuously find their way into new, more demanding applications and industries. However, in order to achieve the optimum performance and properties for a specific application plastics are usually filled with additives, fibres and/or they have their molecular structure altered. Thus, extensive analysis and characterisation is required to achieve the desired properties and continuously monitor the quality of the products. Thermal analysis methods, which deal with the material behaviour as a function of temperature are critical in polymer characterisation. The most typical members of Thermal analysis are: differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), thermal mechanical analysis (TMA) and dynamic mechanical analysis (DMA). Herein, we will focus on the TGA.

Thermogravimetric analysis, TGA, measures the rate and the amount of weight change as a function of temperature or time in a controlled atmosphere. The weight of the tested specimen usually decreases due to material decomposition or evolving volatile gases, but it could also gain weight through gas absorption or chemical reaction. TGA yields critical and valuable information on the composition and thermal stability of plastics and polymer based materials and it is an important tool in the material development, QA/QC and failure analysis sectors. The obtained data can include the content of volatiles, inorganic fillers, carbon black and the onset of decomposition. TGA methods have been widely included in industry standards such as, ISO 11358-1/2/3, ASTM E1131, E2105 (plastics and composites) and ISO 9924-1/2, ISO 21870, ASTM D6370 (rubbers).

The NETZSCH TG 209 F3 system

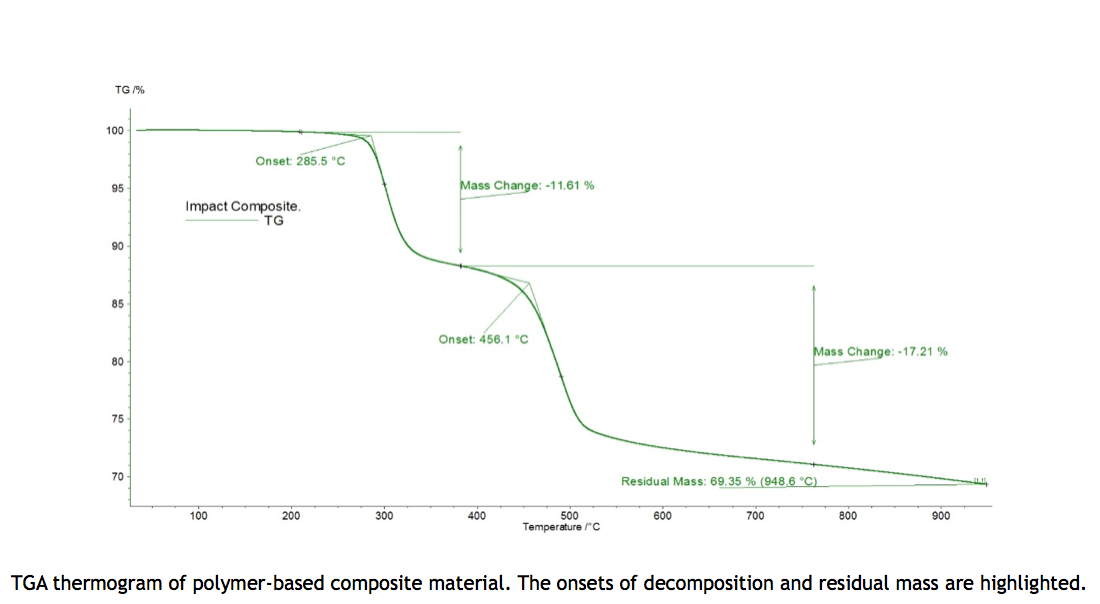

The basic components of a TGA are the analytical microbalance and the furnace. A specimen, typically from 5-100 mg, placed on the microbalance is heated in a constant rate from ambient to up 1100 °C in a dynamic environment nitrogen or oxygen. During heating the weight loss recorded as a function of time or temperature. Figure below shows a characteristic TGA thermogram of a polymer-based composite material.

The specimen which is PVC based was taken from novel product developed by Impact Solutions. PVC decomposes in a two-step process. First step is the dechlorination processing evolving HCl close to 300 °C and the second step is loss of hydrocarbons at around 450 °C. According to the thermogram shown below the steps are typical to the decomposition of PVC. In addition, the total weight loss during the composition step is 30.65%. This means that the percentage of inorganics in the composite product tests is 69.35%.

The above is just a typical of example which shows the significant importance of thermogravimetric analysis, TGA. Impact Solutions, equipped with a state-of-the-art NETZSCH Tarsus F3, is capable of undertaking TGA tests for routine QC/QA, material development and failure analysis. Additionally, Impact’s TGA is also coupled a FTIR for real time qualitative and quantitative material characterisation. For more information don’t hesitate to contact us.

Be sure to stay in touch by following us on Facebook, LinkedIn and Twitter.