Shelf-life testing is a crucial aspect of product development and quality assurance, designed to ensure a product’s longevity and reliability under various conditions. One essential testing method that accelerates the effects of time by exposing materials to elevated temperatures is known as “heat aging testing.” This allows manufacturers across various industries to predict how their products will behave over time, both under normal and extreme conditions.

What is Shelf-Life Testing?

Shelf-life testing involves evaluating a product to determine how long it will remain usable, safe, and effective under typical storage conditions. This testing applies not only to perishable goods like food but also to non-perishable items such as pharmaceuticals, medical devices, packaging, and consumer products.

The goal of shelf-life testing is to ensure that a product maintains its integrity, function, and safety from manufacture to the end-user. Testing typically involves a combination of real-time studies, where products are stored under normal conditions, and accelerated aging techniques, in which factors like temperature and humidity are manipulated to simulate long-term use within a shorter timeframe.

Accelerated Aging of Sterile Packaging and Medical Devices

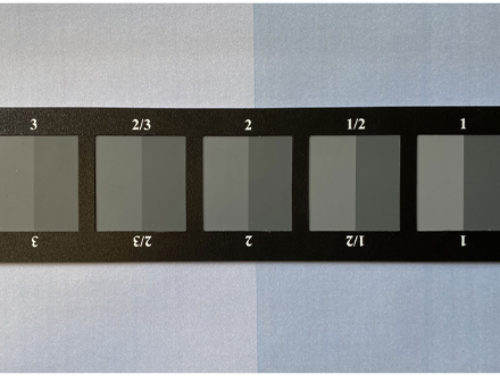

ASTM F1980 is one of the key standards for shelf-life testing that Impact Solutions utilizes. This guideline is specifically developed to help manufacturers estimate the shelf life of sterile medical packaging and devices. It provides a framework for simulating the long-term effects of aging by exposing products to controlled elevated temperatures, thereby compressing the timeline to predict their behaviour over years of storage. The ASTM F1980 standard recommends specific temperature and time parameters to ensure accurate aging results within weeks or months, making it especially valuable for medical and pharmaceutical products that require long-term sterility and stability.

Heat Aging for Shelf-Life Testing

Heat aging is one of the most widely used methods for accelerating shelf-life tests. Temperature plays a critical role in the chemical and physical processes that lead to product degradation, making heat aging testing particularly effective. By exposing items to elevated temperatures over a defined period, manufacturers can simulate the effects of time, allowing them to predict product performance and longevity. This process enables companies to assess risks such as material degradation and loss of effectiveness.

Examples of Shelf-Life Testing Relevant to ASTM F1980:

- Pharmaceutical Packaging: Ensures that medications maintain their efficacy and safety throughout their shelf life.

- Sterile Surgical Instruments: Evaluates the integrity and sterility of tools used in medical procedures.

Examples of Heat Aging Tests in Other Industries:

- Cosmetics and Personal Care Products: Tests ensure that active ingredients remain stable and effective over time.

- Food Packaging: Assesses the durability of packaging materials to prevent spoilage and maintain food safety.

- Electronics Components: Predicts the long-term performance and reliability of components subjected to temperature fluctuations.

- Automotive Parts: Evaluates how high temperatures affect the durability of components and materials used in vehicles.

Get in touch

At Impact Solutions, we offer a range of standard and bespoke shelf-life testing services tailored to your needs. Whether you’re in the pharmaceutical, food, cosmetics, or automotive industry, our expertise can help you maintain quality and compliance. Contact us today to learn how we can support your product development and safety assurance.