Surface roughness or roughness, in short, is the measure of deviations in the direction of the normal vector of a real surface from its ideal form. If the deviations are small surface is smooth, if they are large, the surface is rough.

Significant differences in surface roughness can obviously lead to visual differences between two identically manufactured parts. However, even if the differences are not visible by naked eye, acute differences can affect the amount of wear, ability to form a seal when a part makes a contact with another surface, paint or coating ability of the part etc. The internal surface roughness of pipes can affect the flow of fluid resulting in pressure and energy losses. Therefore it becomes necessary to measure the roughness of a surface.

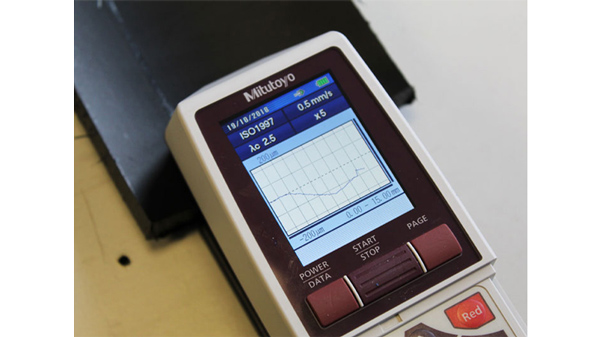

Impact Solutions use the state of the art Mitutoyo Surftest SJ-210 Portable Surface Roughness Tester. This tester is portable, hence making it possible to perform measurements on site and on parts with difficult to access areas. The tester uses a stylus type probe of radius 5µm. It comes with a calibrant to calibrate and perform equipment checks.

The Surftest SJ-210 complies with the following standards: JIS (JIS-B0601-2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO-1997, and ANSI.

It can perform the following measurements:

Ra – arithmetical mean roughness value.

Rmr(c) – material component of the profile.

RSm – mean peak width.

Rt – total height of the roughness profile

Rzi – greatest height of the roughness profile

Rz1max – maximum roughness depth

Rz – mean roughness depth

Be sure to contact a member of our team to learn more about the testing process and what you can expect from the impact team!

To learn more about us, be sure you are following us on Facebook, LinkedIn and Twitter.