UL94 Horizontal Burning Test

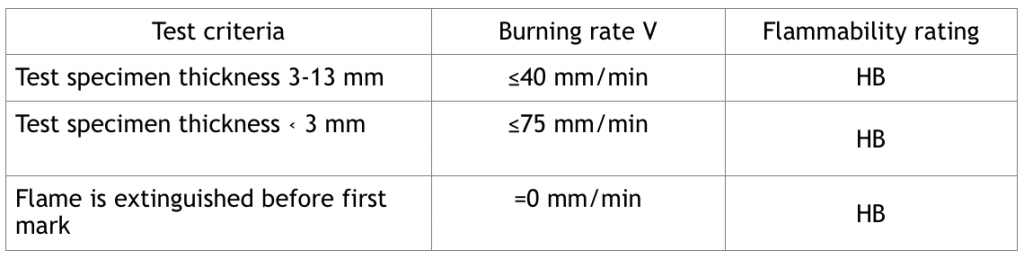

The horizontal burning test, for classifying materials HB, evaluates the burning rate of a specimen in mm/min taking into account its thickness.

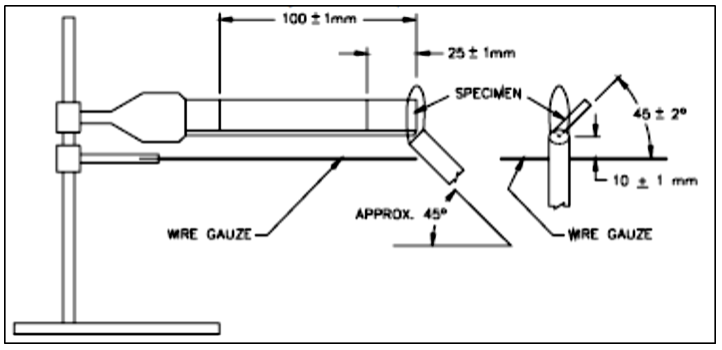

Specimen: Two sets of three specimens with nominal dimensions 125 mm x13 mm and thickness not more than 13mm.

Specimen conditioning: Condition the specimens at 230C and relative humidity 50% for minimum of 48 hours.

Gas flow: Set the methane gas flow to 105 ml/min. Adjust the flow and air intakes of the burner to get a clean blue flame 20mm high.

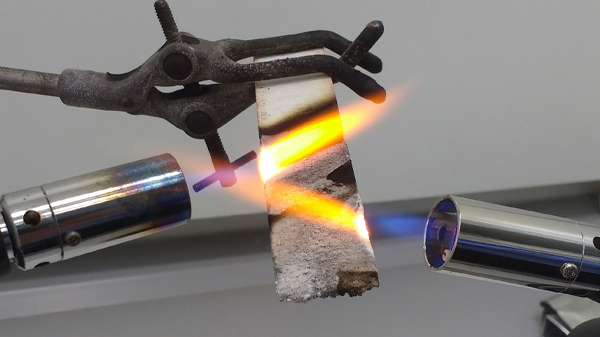

Flame application: 20mm Bunsen burner flame

Flame application time: 30 seconds. If the flame front reaches the first 25mm mark within 30 seconds the flame application is discontinued.

Measurements:

A – Whether the flame passed the 25mm mark.

B – Whether the flame passed the 100mm mark.

C – The elapsed time between 25mm and 100mm mark, if the flame passed the 100mm mark.

L – The damaged length between the 25mm and 100 mm mark.

V – The calculated liner burning rate in mm/min.

Based on the measured values use the following table to classify the material as V-0, V-1

Test setup: The Bunsen Burner and the test specimen is set up as shown in the test schematic.