ASTM D 4808

ASTM D 4804 test method describes a small scale laboratory test for determining the comparative burning characteristics of solid plastic materials that due to specimen thickness and non-rigidity distort or shrink when tested under ASTM D 3801.

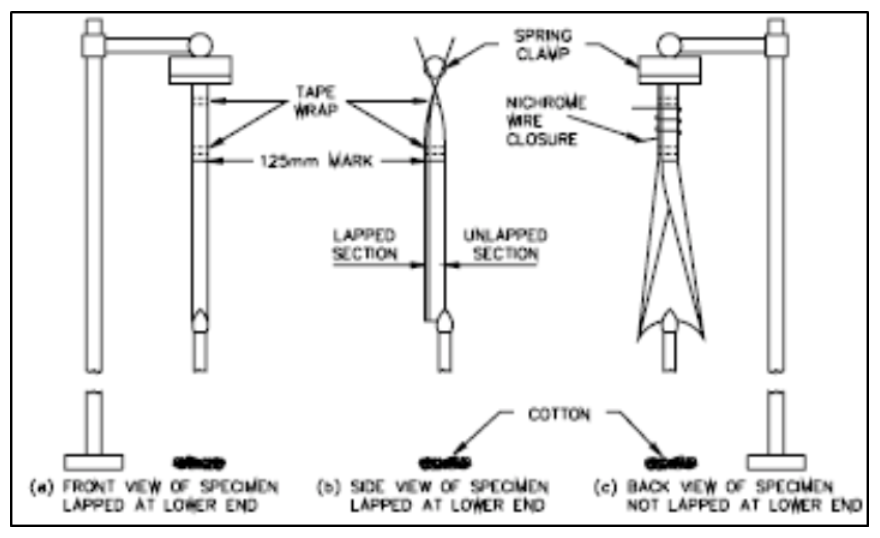

Specimen: Four sets of 5 specimens with nominal dimensions 200mm x 50mm and in minimum and maximum thickness.

Specimen conditioning: Two sets of 5 specimens per sample were conditioned as follows:

i. First set at 230C and relative humidity 50% for minimum of 48 hours.

ii. Second set in an air circulating oven for 168 hours at 700C and then cooled in a desiccator for minimum of 4 hours.

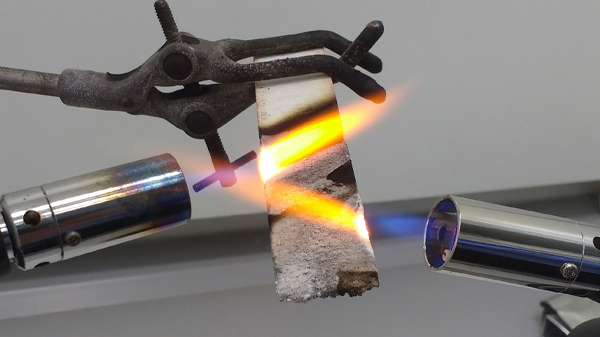

Gas flow: Set the methane gas flow to 105 ml/min. Adjust the flow and air intakes of the burner to get a clean blue flame 20mm high.

Flame application: 20mm Bunsen burner flame

Flame application time: 2 x 3 seconds application. The second flame application time begins as soon as the ignited specimen is extinguished or immediately if the specimen does not ignite.

Measurements:

A – Duration of flaming after first flame application (seconds).

B – Duration of flaming after second flame application (seconds).

C – Duration of glowing after second flame application (seconds).

D – Whether or not specimens burn up to the 125mm mark.

E – Whether or not specimens drip flaming particles which ignite cotton swatch.

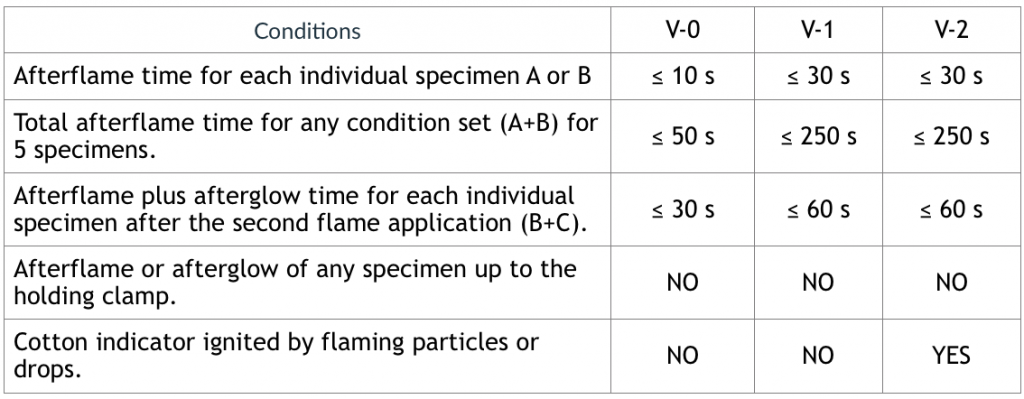

Based on the measured values using the following table to classify the material as VTM-0, VTM-1 or VTM-2.

Test setup: The Bunsen Burner and the test specimen is set up as shown in the test schematic.