ISO 9772

ISO 9772 test method describes a small scale horizontally oriented burning test procedure for comparing the:

- relative rate of burning

- the extent of burning

- the time of burning of cellular polymeric materials having a density less than 250 kg/m3.

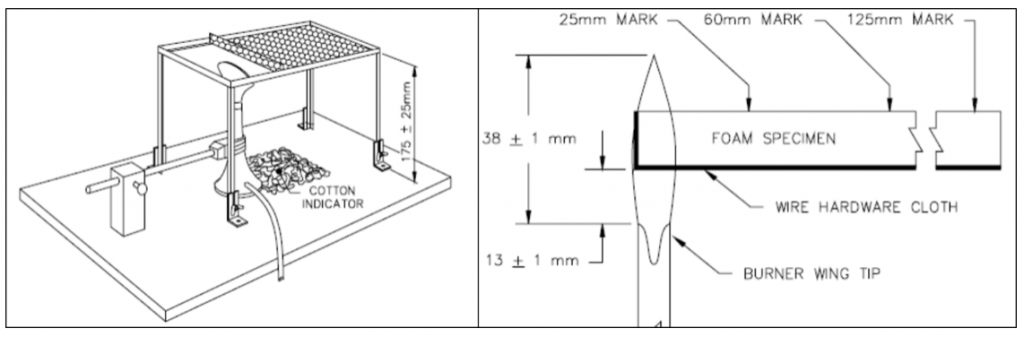

Specimen: Four sets of 5 specimens with nominal dimensions 150mm x 50mm and in minimum and maximum thickness.

Specimen conditioning: Two sets of 5 specimens per sample were conditioned as follows:

i. First set at 230C and relative humidity 50% for minimum of 48 hours.

ii. Second set in an air circulating oven for 168 hours at 700C and then cooled in a desiccator for minimum of 4 hours.

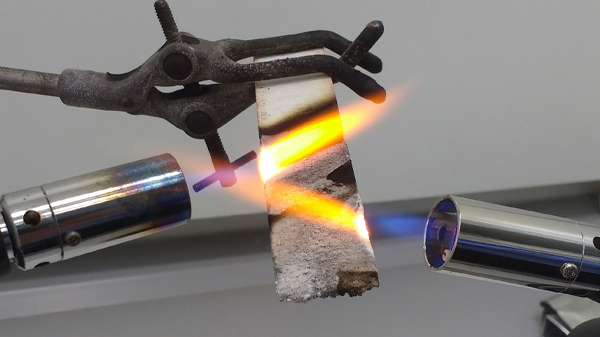

Gas flow: Attach a wing tip to the Bunsen burner, and adjust the gas flow till a clean blue flame 38mm high is obtained.

Flame application: 38mm Bunsen burner flame.

Flame application time: 60 seconds.

Measurements:

A – The flaming ceases (afterflame).

B – The flaming and glowing ceases (afterglow).

C – The flaming or glowing front reaches the 125mm mark or when the specimen ceases burn or glow before 125mm mark.

D- The distance specimen burnt up to 60mm mark or if the 60mm mark passed.

E- The dripping particles ignited the cotton placed below.

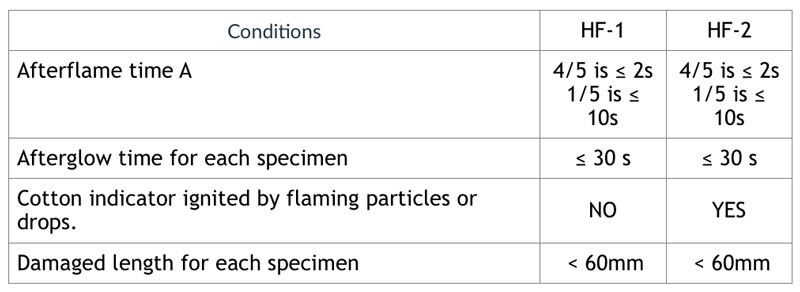

Based on the measured values use the following table to classify the material as HF-1 or HF-2.

4/5 means 4 specimens out of a set of 5.

1/5 means 1 specimen out of a set of 5.

Test setup: The Bunsen Burner and the test specimen is set up as shown in the test schematic.

Measurements for HBF:

A – The duration of burning between the 25mm mark until flaming or glowing stops or passes 125mm mark.

B – The distance the specimen burned in mm between 25mm mark and where the flaming / glowing stops or up to 125mm mark.

C- Burning rate expressed in mm/min.

Based on the measured values the specimen is classified HBF if it meets the all of the following conditions:

i. Burning rate C expressed in mm/min is less than 40mm/min over a 100mm span.

ii. Each specimen should cease to burn before flaming or glowing reaches 125mm mark.