Pipeline Quality Control

Pipeline quality is important whether using electro fusion or butt fusion welding techniques. It is essential for pipeline quality that the welds are performed correctly to avoid future failures. The majority of failures can be easily prevented through proper procedures, planning, and testing.

QA on a pipeline installation should consist of:

- pre welding procedure specification

- auditing and oversight of procedures submitted by contractors

- ensuring proper qualification of welders

- on site supervision of welders prior or during installation

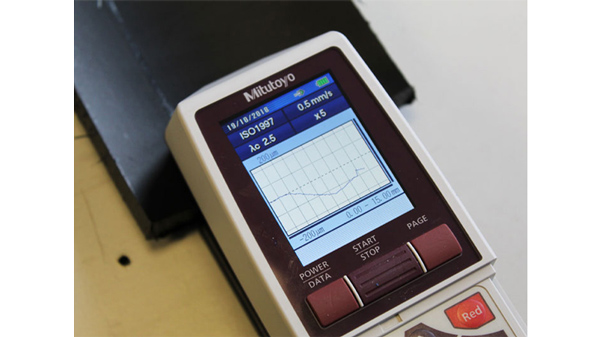

- non destructive analysis using Impact Solutions’ patented ndt technology

- destructive testing of sample welds as per the pre welding procedure specification

- feedback loops for preventive and corrective actions for any issues found during testing

Pipeline Quality Pre-Specification

Impact Solutions can advise and create pre-weld specifications during tendering or prior to contractors starting work. This specification will identify high risk welds, and pinpoint an acceptable programme of QA. Procedures can be created and instructions issued to welders and inspectors prior to work beginning.

Auditing and Training

Through our partnership with PE WeldRight Ltd (Barrie Collins) we offer auditing services, both prior to welding commencing and during the welding process. Auditing can involve ensuring operators are correctly trained (to appropriate industry standards), that machinery is within specification and that procedures are being followed. As with our other services this is 100% independent from any man, machinery or material supplier allowing you confidence in the results obtained.