Peel Adhesion Test – 90˚ and 180˚ Peel Test

The peel adhesion test is used to determine the force required to de-bond two components joined by an adhesive. The test result, also known as bond strength, is generally represented as N (force to de-bond) / 25mm or 50mm (depending on specimen width).

The peel adhesion test can be used for:

- Quality control – where the glued component needs to meet a minimum bond strength value.

- Adhesive curing – determine the optimum temperature and pressure required to give the maximum bond strength.

- Adhesive behaviour – determine the effect that temperature, humidity, and environmental conditions can have on the bond strength.

Applications: Adhesives are widely used in various industries including textiles, fabrics, labels, laminates, and composites. Peel adhesion testing applies to almost all components that are bonded together using adhesives.

900 peel test

In 90 degree peel test, a constant 90˚ angle is maintained whilst the two glued components are peeled apart. The average load required to separate the two, over the length of the specimen is recorded and expressed as N/25mm. Other methods of expressing test results include average peak/trough loads and customer-defined calculations.

Sample requirement – generally a set of 5 specimens of size 20 mm width and 200 mm length are required. These can be directly cut from the product or prepared under laboratory conditions. One of the two glued components should be flexible enough to be bent 90˚ without breaking.

Test setup – The test specimen is clamped on a free-moving table. From one end of the specimen, either mechanically or chemically de-bond or separate the two components, 40mm in length. The separated top component is clamped in the moving vice, and attached to a moving crosshead.

The two components are peeled apart by the movement of the crosshead. The test speeds are generally 300mm/min or as defined by a standard. The free-moving table is attached to the crosshead using a pulley and rope mechanism, such that the traverse movement of the table is at the same rate as the crosshead movement, thus maintaining a constant 90˚ angle between the two components.

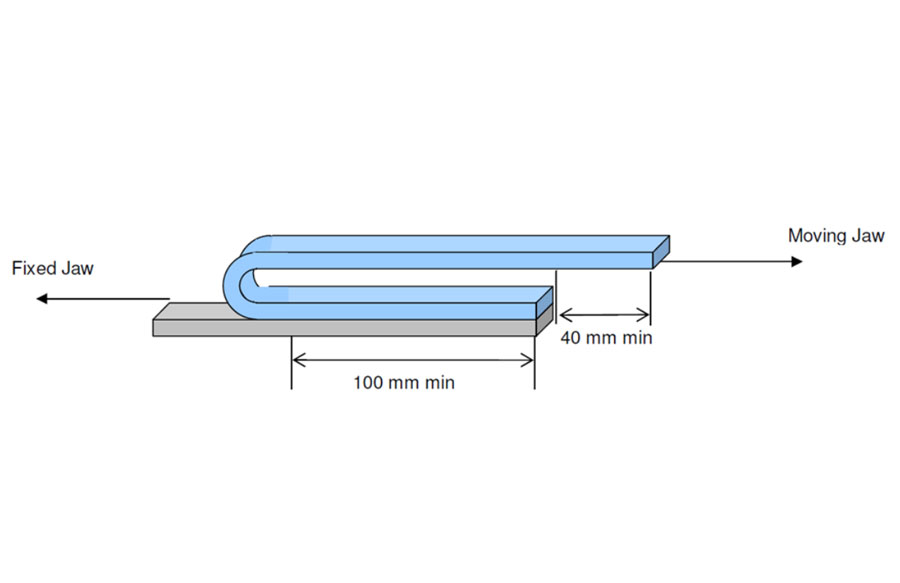

180˚ peel test

In the 180-degree peel test, a constant 180˚ angle is maintained whilst the two glued components are peeled apart. The average load required to separate the two, over the length of the specimen is recorded and expressed as N/25mm. Other methods of expressing test results include average peak/trough loads and customer-defined calculations.

Sample requirement – generally a set of 5 specimens of size 20 mm width and 250 mm length are required. These can be directly cut from the product or prepared under laboratory conditions. One of the two glued components should be flexible enough to be bent 180˚ without breaking.

Test setup – The test specimen is clamped on a fixed grip. From one end of the specimen, either mechanically or chemically de-bond or separate the two components, 140mm in length. The separated top component is clamped in the moving vice, and attached to a moving crosshead.

The two components are peeled apart by the movement of the crosshead. The test speeds are generally 300mm/min or as defined by the standard. The following figure shows the test schematic.

In addition to the peel adhesion test, Impact Solutions offers a range of services and testing. To view our full list of testing and services, click here.

If you are interested in our testing, feel free to contact a member of our team. In the meantime, be sure to follow us on Facebook, Twitter and LinkedIn.