Flexural Testing

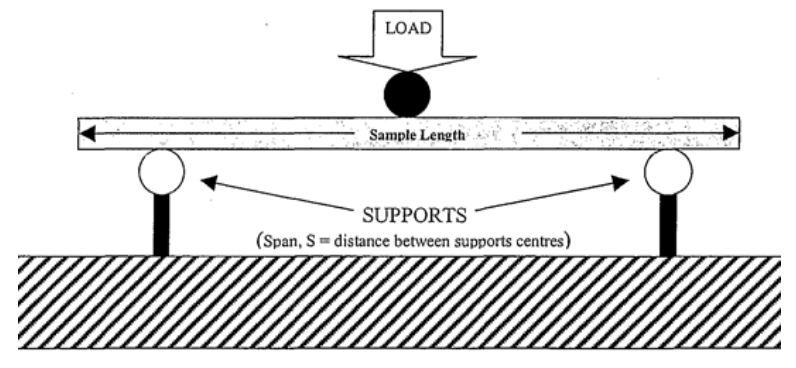

A 3-point flexural test is a type of mechanical test used to measure the strength and elasticity of a material by applying a bending force at three points. In this test, the sample is placed horizontally on two supports with a fixed distance between them, and a load is applied at the center of the sample using a third support. As the load is increased, the material begins to bend, and the amount of deflection or deformation is measured at the center of the sample. The resulting data can be used to calculate the flexural strength and modulus of elasticity of the material, which are important properties in designing structural components such as beams and columns.

3-point flexural testing is commonly used in industries such as construction, aerospace, and manufacturing.

There are a variety of standards related to a three-point bend test, Impact Solutions are UKAS accredited to conduct ISO 178:2019 and can also conduct ISO 14125, ASTM D672, ASTM D55365, IPC TM-650, and IEC 61189-2:TM20. We can also conduct one-point bend tests and four-point bend tests if required.

This test is suitable for plastics and composite materials. Impact uses an Instron universal tester (3382) to carry out flexural testing. In addition, we are also equipped with a special environmental chamber from Instron, which allow us to carry out at sub-ambient or above ambient conditions.

In summary, flexural testing can aid designers & moulders to select the most suitable material for the intended purpose by understanding the following properties:

-Flexural Strength

-Maximum Flexural Stress

-Maximum Strain

-Stress at Strain

-Flexural Secant Modulus of Elasticity

-Flexural Chord Modulus of Elasticity

-Failure Mode and Location