ISO 16474 – testing paints & coatings to last

Paints and varnish coatings are used on various materials and products, both indoors and outdoors, where they are exposed to sunlight and environmental conditions. It is essential to evaluate how these coatings perform against weathering elements such as solar radiation, heat, and moisture. These factors can alter the physical appearance and chemical properties of coatings over time. ISO 16474 is an accelerated weathering standard designed to simulate these conditions using artificial light sources in a controlled laboratory environment.

Testing Biodegradable Paints for durability

As the demand for sustainable and environmentally friendly products grows, biodegradable paints are being developed to offer an eco-friendly alternative to traditional coatings. These paints are designed to break down naturally over time, reducing their environmental impact. ISO 16474 testing is suitable for assessing the durability and weathering resistance of biodegradable paints, ensuring they meet performance requirements while maintaining their biodegradable properties. The development of such coatings represents a significant step in improving a widely used product and promoting sustainability in various industries. Further biodegradability testing can also be conducted for biodegradable paints and coatings to assess and understand how quickly and completely these materials break down.

ISO 16474 Methods

ISO 16474 consists of several parts, each specifying different laboratory exposure methods:

ISO 16474-1: General guidance

ISO 16474-2: Xenon-Arc Lamps

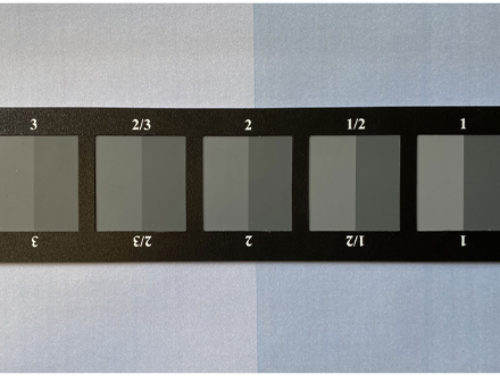

This method exposes paint and varnish specimens to xenon arc light in the presence of moisture to replicate real-world daylight exposure, including filtered daylight through windows. Testing equipment must control irradiance, temperature, humidity, and wetness. Impact Laboratory uses Q-Sun Xenon Arc test chambers to meet these requirements. Exposure conditions vary based on the combination of filters, humidity levels, temperature, and light cycles. A control specimen is recommended to allow for comparative analysis.

ISO 16474-3: Fluorescent UV Lamps

This method exposes test samples to fluorescent UV radiation, heat, and moisture in controlled conditions. Variations in testing parameters include the type of fluorescent lamp (spectral power distribution), irradiance level, temperature, and wetting methods. Wetting is typically achieved through water vapour condensation or spraying demineralised/deionised water onto the specimens.

ISO 16474-4: Open-Flame Carbon-Arc Lamps

This method simulates exposure to open-flame carbon arc lamps, combined with heat, humidity, and moisture. Test specimens are subjected to glass-filtered radiation, and conditions can be adjusted by altering the light filter, exposure temperature, and wetting cycle. Open-flame carbon-arc light sources use multiple carbon rod pairs coated with metal salts, producing ultraviolet, visible, and infrared radiation as they burn. The light reaching the specimens is filtered through different types of glass.

Why Choose Impact Solutions?

Impact Solutions operates a UKAS-accredited accelerated weathering laboratory capable of testing a broad range of products and materials across numerous industries. We offer competitive pricing and deliver dependable, consistent results for assessing and enhancing material durability.

To learn more about our accelerated weathering services, contact our team today.

Follow us on LinkedIn for our latest updates.