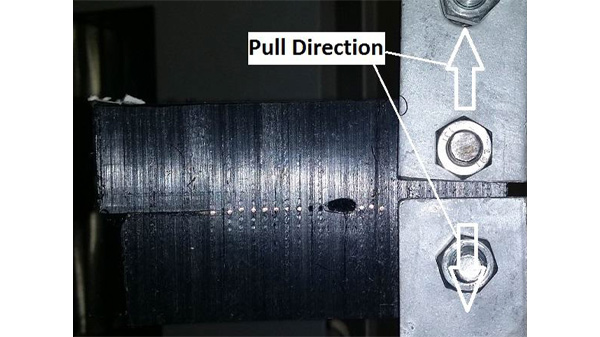

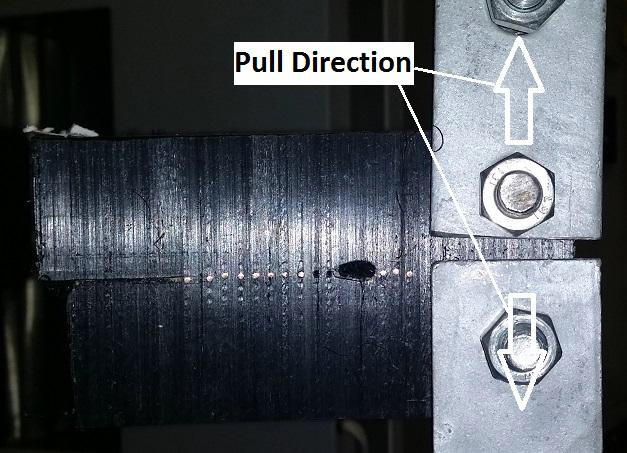

Electrofusion weld joints are tested using the double cantilever test. The samples are pulled apart at a rate 25 mm/min using an Instron tensile testing machine until the pipe and coupling have completely separated. A force/displacement graph is recorded for each sample and the peak force is also captured. The test setup is as in the picture below;

As with Butt fusion joints, the standard (WIS 4-32-08) requires a visual inspection of the weld interface to be undertaken once the test has completed. Unfortunately, the reference pictures in WIS 4-32-08 are unclear, which makes interpreting borderline specimens difficult. Below are some examples from Impact’s recent work.

Ductile Electrofusion Weld

Ductility is what we want to see when undertaking destructive weld testing. As you can see in this picture the plastic has been pulled into peaks. This would be a clear pass.

Brittle Electrofusion weld

This is not what you want to find. A brittle pipe weld will be susceptible to failure once pressurised. Brittle areas can occur for a number of reasons, but the most common is contamination due to mud.

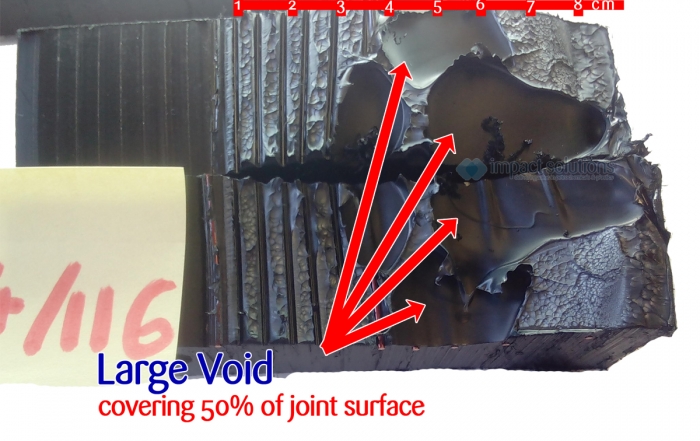

Voids in an Electrofusion weld

Voids are bad, as it means there is no surface contact between the joint and the coupler. The WIS 4-32-08 standard states that the joint must be at least 75% ductile, so if a void is more than 25% of the surface area on any pulled joint section, then the whole weld will be declared a failure.

Below we have a joint which would pass, despite the presence of a void.

The next sample is also displaying ductile behaviour, but in this case, the void is greater than 25% of the surface area. In this case, the weld would be failed.

For more information, contact a member of our team today!

Be sure to also follow us on Twitter, LinkedIn and Facebook.