The density of plastic varies significantly from one sample to another. This is happening due to the unique character of the polymers to partially crystallize at the solid state, yielding a different degree of crystallinity and consequently different densities. It is well known that the degree of crystallinity, which regulates the crucial mechanical properties of a polymeric material, is directly related to the density of plastic. The direct determination of the degree of crystallinity of a polymeric material sometimes could become a relatively complicated task, especially in the cases of copolymers and/or a large number of samples. On the other hand, the determination of the density offers an accurate, reliable, and cost-effective means of assessing the degree of crystallinity of the polymeric samples. One of the most important ways to determine the density is by the use of a density gradient column (ASTM D1505 & ISO 1183 Method D standards). A density column is comprised of a tall glass tube that contains a mixture of two liquids with different densities. When the processes of mixing the two liquids and the filling of the glass tube are done carefully, then the density of the resulting column is increased almost linearly from the top of the column. A controlled temperature environment, usually set at 23 oC is also required to maintain this uniform density gradient. To calibrate the column, float beads of known density are used. A calibration graph is then built with the density versus the height at which beads settle/float. The liquids used to build the density gradient should be chosen to cover the required range of density and to be compatible with the tested samples (avoid absorption, chemical reaction, etc.). When the gradient column is ready and the calibration line is built then the tested specimen is dropped carefully into the column and recorded the height at which it will settle. This height is put against the calibration line and the density of the sample is determined. To ensure that reliable density data are obtained the following tips should be taken under consideration:

- Remove the air bubbles from the liquids because these could inhibit the calibration floats or samples from settling properly. This could be achieved by the use of helium gas for example

- Before placing the calibration beads and samples into the column they should be wetted with one of the density liquids to minimize the possibility of trapping any air bubbles into the system.

- The temperature of the column should be always monitored and controlled. This could be achieved by surrounding the columns with a circulating water jacket.

Determining the Density of Plastic

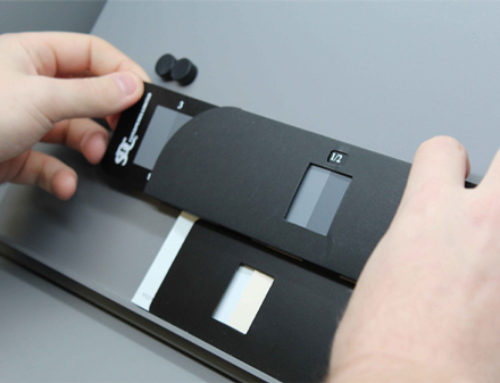

In the particular case of polyethylene samples (average density 940 kgm-3) the gradient column is being built using mixtures of iso-propanol and water with a density gradient from approximately 904 to 960 kgm-3 (as per ISO 1183-2 D). Impact Solutions, which is a UKAS-accredited testing laboratory No. 0402 for determining the physical and mechanical properties of plastic materials has recently purchased a state-of-the-art triple-density gradient column machine from Ray-Ran, Warwickshire, UK (Figure 1). This allows Impact to simultaneously obtain quickly and accurately the density properties of three different types of polymers. Some of the technical advancements of Impact’s new density columns are the following:

- A trammel-guided sight connected to a position encoder which transfers the height position to a microprocessor is used to obtain the density without the need to plot graphs.

- A microprocessor system to accurately determine the density of the sample.

- An advanced pump to fill gradually and in a controlled manner the glass tube with the mixed liquids.

- Digital Temperature Controller to ± 1 C.

Impact Laboratories aim to use our extensive expertise and knowledge of polymer characterisation combined with our advanced equipment, to provide our customers with reliable, fast, and cost-effective information regarding their polymer-based products.

Figure 1. Density column machine from Ray-Ran coupled with a microprocessor for measuring the density of plastic.

For more information regarding Impact’s capabilities on polymer testing please contact us, and one of our plastic experts will be delighted to help you out.

Follow us on Facebook and LinkedIn to stay up-to-date with our newest developments.