What is QUV Accelerated Weathering Testing?

Impact Solutions can also offer UV testing in their Q-Lab QUV accelerated weathering tester unit. The QUV unit sits alongside our other Q-Lab Q-SUN Xenon Arc Test Chambers and is able to perform a whole selection of tests where the UV Only part of the light spectrum is required.

Why use UV light?

The suns spectrum is made up of many different types of light including, UV, infrared and visible. The UV part of the sun’s light is the part that can be most damaging, this is the part that will give you sunburn and skin cancer and so this is also the part that is most likely to cause damage to your materials and samples.

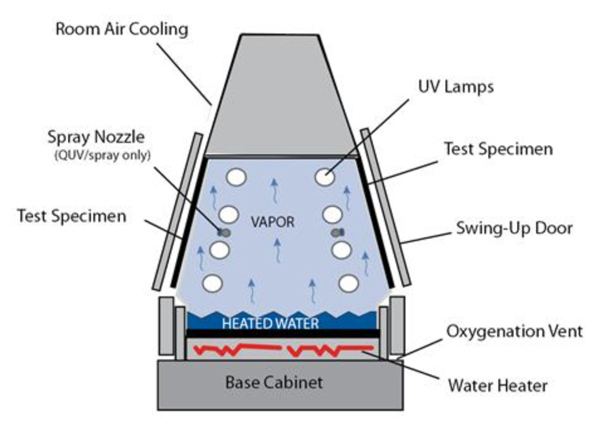

There are several UV options available to run, including UVA, UVB (UVB being the harsher of the two options) and UVC. To simulate outdoor weathering, the QUV accelerated tester reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV unit exposes materials to alternating cycles of UV light and moisture at controlled, elevated temperatures to reproduce the damage that occurs over months or years outdoors. Essentially the QUV accelerated weathering tester unit can handle all weathering conditions and is the go-to accelerated weathering model unit.

Have a question?

Speak to our specialists

Our QUV accelerated weathering tester unit is ideal for doing your development work and getting your materials stable in UV light.

This type of testing is very popular in the plastics, coatings, automotive and textiles industry.

QUV accelerated weathering tester will be able to run tests such as:

| ISO 4892-3 | EN13523-10 | ASTM D4587 |

| ASTM G155 | EN 1297 | ASTM D4329 |

| SAE J2020 | EN 12224 | EN 1062-4 |

| ASTM G154 | ISO 16474-3 | ASTM G151 |

| ISO 11997-2 | ASTM D5208 | EN927.6 |

| ASTM D4799 | PAS 820 | ASTM D4434 |

| GB/T 31881 |