Impact Solutions was approached by a client in the building industry, regarding accelerated weathering testing of a new roof light product they wished to develop. It is generally accepted within the UK construction industry that Xenon accelerated weathering testing facilities using a 102 min dry/18 min wet cycle can represent daylight exposure in NE Europe with an acceleration factor of approximately x8. 45 years lifetime, therefore, requires nearly 6 years accelerated weathering testing in a Xenon test chamber.

Exposure to UVA ageing is recognised as more severe, but the correlation factor with natural weathering is lower. The acceleration factor for UVA exposure is estimated to be roughly x40.

Accelerated Weathering Testing program proposal

It was proposed by Impact that parallel work using Xenon and UVA exposure would be beneficial to determine the likely 45-year cycle of the product. The aim would be to provide an overlap between the data from the 2 exposure methods to indicate that UVA exposure could be used to provide the long term assurance but using much less time under accelerated weathering testing. In this case accelerated weathering testing was undertaken for just 35 days, rather than 6 years.

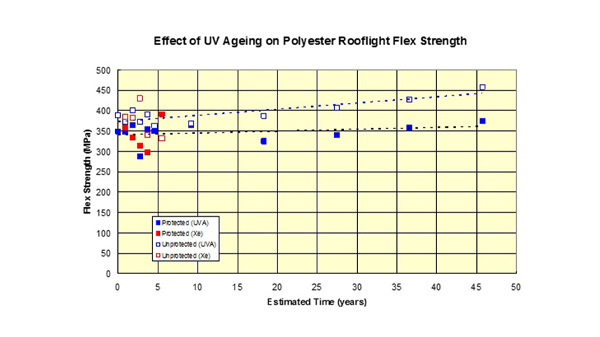

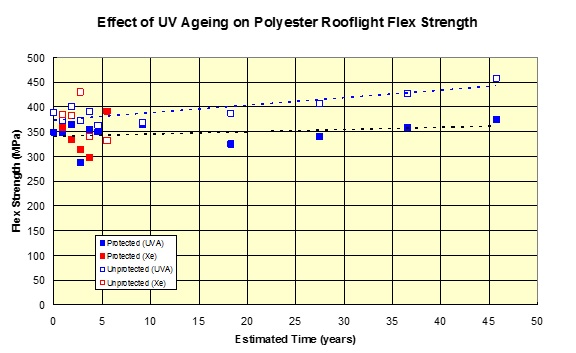

Materials used to sample the accelerated weathering testing were polyester GRP panels cut from the latest rooflight product development. Both protected and unprotected surfaces of these panels would be exposed to Xenon 102d/18w and UVA cycles. The basic evaluation parameter for the mechanical performance of the material would be the flexural strength as determined by ASTM D790. Samples would be removed from the weathering machines at set times and their flexural strength tested.

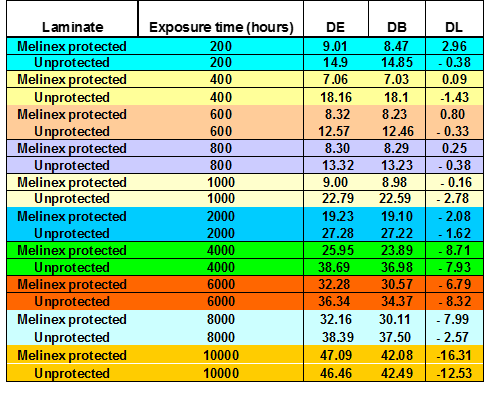

The outcome of the programme was graphs of flexural strength versus UV exposure time for the different exposure types for both protected and unprotected polyester panel surfaces. Additionally, there was a series of observations regarding colour change and integrity of the material as shown in the graphs below:

DE is a measure of the overall change, that is, both colour and lightness change DB is a measure of the change in yellowness/ blueness – positive changes in values represent increased yellowness. DL is a measure of the change in lightness /darkness – positive values represent an increase in lightness (in general negative values are to be expected)

Despite clear UV degradation of the polyester roof light GRP laminate following accelerated weathering testing, there is no detectable deterioration in flexural modulus or strength after an estimated 45 years exposure. This is the case for exposure on both protected and unprotected surfaces and is particularly encouraging for the long term performance of polyester roof lights of this construction.

A 45-year service life for such a product can, therefore, be predicted with confidence.

To find out more about how Impact Laboratories can apply the same knowledge to your products, or to find out how we can tailor a testing package to your needs, contact us now.

Be sure to also follow us on Twitter, Facebook and LinkedIn.