ASTM D 5048

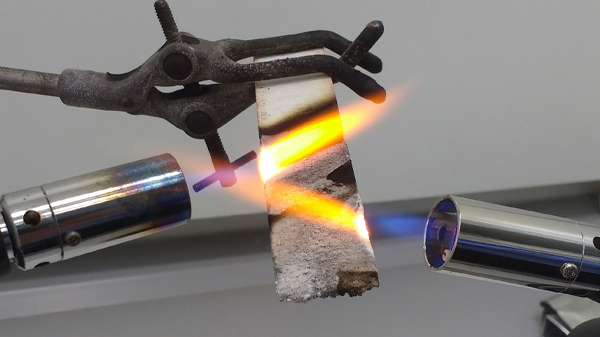

ASTM D 5048 evaluates both the burning and afterglow times and any holes that are formed as well as dripping of the burning test specimen using a 125mm flame.

Specimen: Four sets of five bar specimens and three plaque specimens. The bar specimens will have nominal dimensions 125mm x 13mm and thickness not to exceed 13mm. The plaque specimen will have nominal dimensions 150mm x 150mm and thickness not more than 13mm.

Specimen conditioning: Two sets of 5 bar specimens and 3 plaque specimens per sample to be conditioned as follows:

i. First set at 230C and relative humidity 50% for minimum of 48 hours.

ii. Second set in an air circulating oven for 168 hours at 700C and then cooled in a desiccator for minimum of 4 hours.

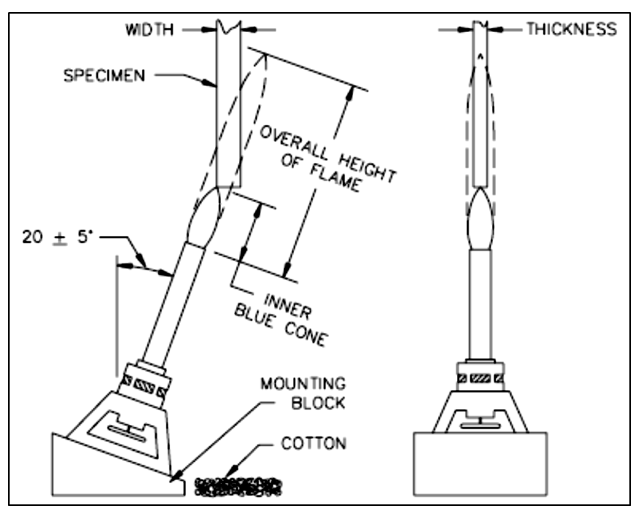

Gas flow: Set the methane gas flow to 965 ml/min with back pressure 125mm of water. Adjust the flow and air intakes of the burner to get a flame 125mm high and inner blue cone 40mm high.

Flame application: 125mm Bunsen burner flame.

Flame application time: 5 x 5 seconds flame applications with intervals of 5 seconds after each application.

Measurements:

After the 5th application of the flame record the following:

A – Afterflame and afterglow time in seconds.

B – Whether or not the flaming particles ignited the cotton.

C – Burn through (hole formation) of any specimens.

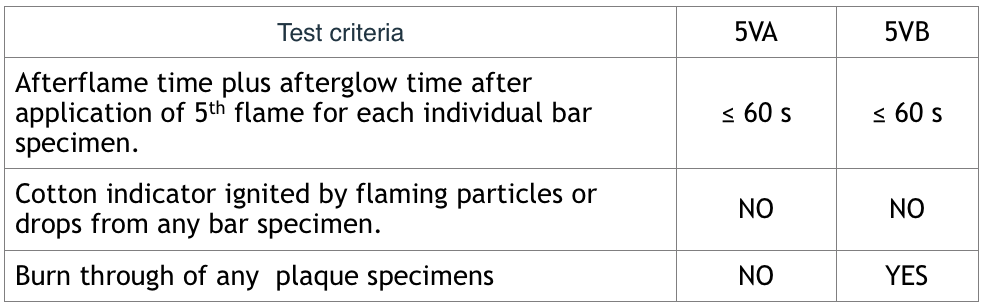

Based on the measured values using the following table to classify the material as 5VA or 5VB.

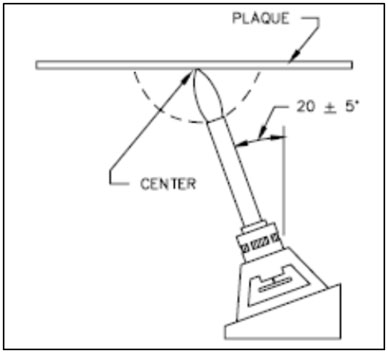

Test setup: The Bunsen Burner and the test specimen is set up as shown in the test schematic.

bar type test specimen

plaque type test specimen