Importance of plastic pipe quality testing

We recently conducted destructive testing of a plastic pipeline system in line with WIS 4-32-08, specifying quality measures for ensuring the integrity of plastic pipe welds. The company who ordered the plastic pipe quality testing have been working with impact for a number of years following a high profile failure at one of their installations. Since then they have used strict quality control guidelines to deliver quality project installations without further incident.

They submitted one qualification weld for a new project they are just undertaking. The purpose of this weld is to qualify the welder, the pipe and the equipment before starting the project. This ensures that the welder, the equipment and the material is all setup correctly and helps avoid failures when pipes are welded in the ground.

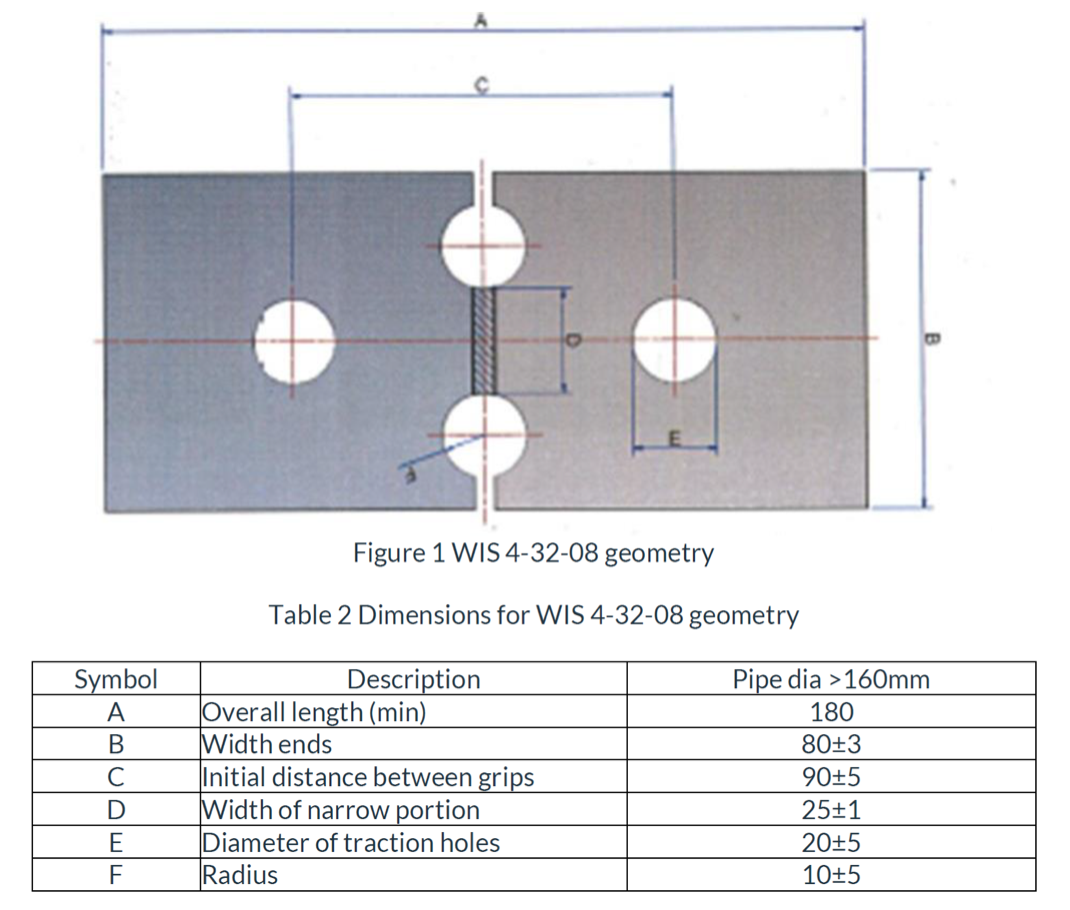

As usual, impact carried out the plastic pipe quality testing in accordance with WIS 4-32-08, which specifies a pull test on a universal test machine (in this case an Instron model). Multiple test specimens are machined to the geometry specified by WIS 4-32-08, with a length of 180mm and a width of 80mm, as detailed below.

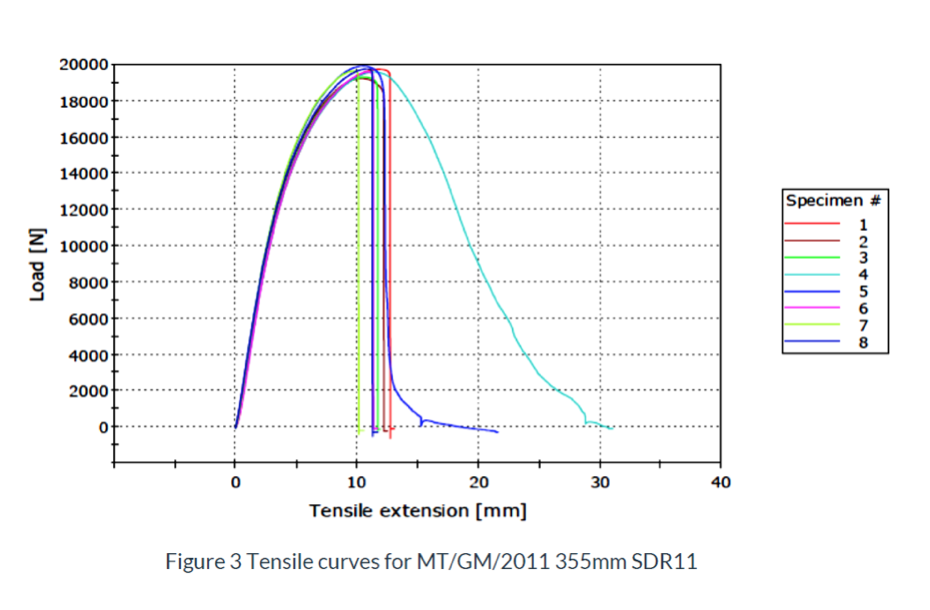

The results of the tensile testing is shown in the graph below.

These results are indicative of brittle failure. You can see the lines rising to a peak load of 20000 N. A good pipe weld would see the load slowly fall off after reaching the peak load (or yield point). In this case, they drop almost immediately to zero. Only specimen 4 has ‘yielded’ showing a ductile weld.

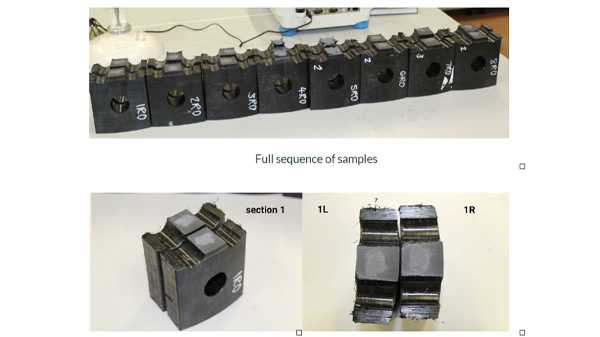

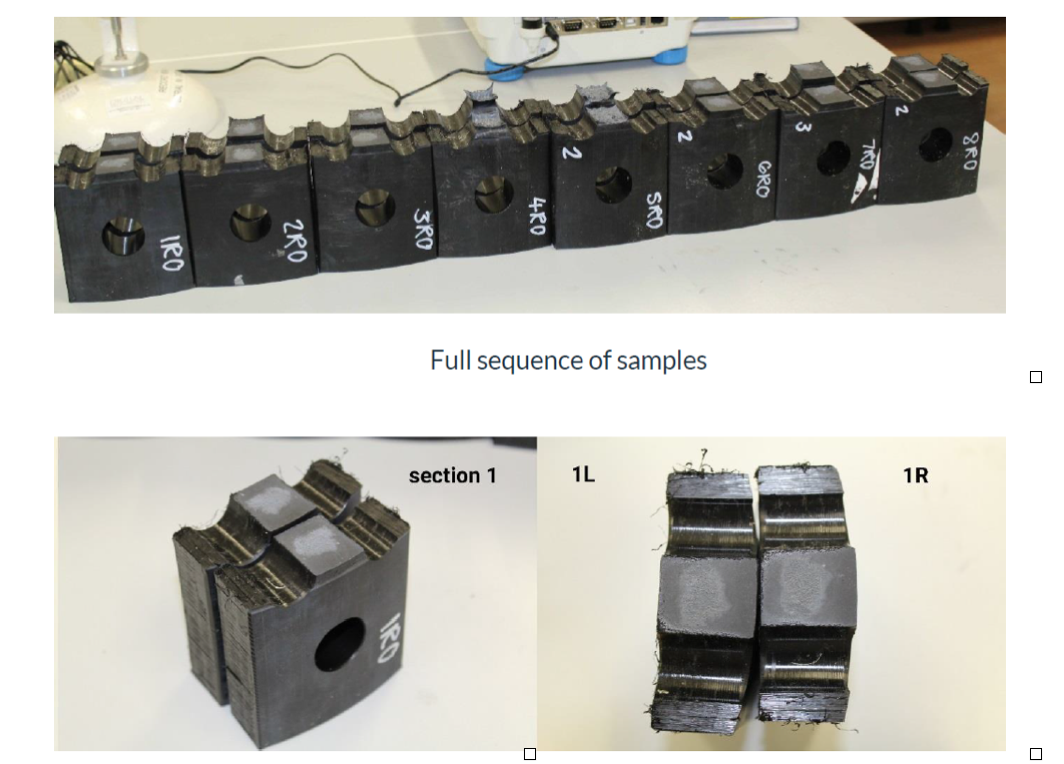

This is how the welds looked after being subjected to tensile testing.

On examining the welds further it was found that the cause of the failure was that a PE 100 pipe had been joined to a PE 80 pipe. However the welder had set the welding machine up to weld PE 100 pipes, and therefore the fusion temperature was not correct. This led to under heating at the weld interface, that contributed to brittle failure.

Because the testing was carried out before the welder started installing the pipeline, this problem was identified and caught before any pipes had been laid. Had the problem not been spotted the whole pipeline would have been installed. It is likely from the peak loads which were obtained by the pipe that the system would have passed the pressurization test without leakages. This would have left a substandard pipeline system installed under the ground and further infrastructure, which would have failed prematurely. The cost of replacing this pipeline would have been significant once account had been taken for:

- Identification of the problem

- Locating the problem

- Removal of infrastructure

- Rework

- Downtime of facility affected by the failure

Impact Solutions are a leading UK test laboratory for pipeline integrity testing, with a vast array of knowledge on destructive and non-destructive testing of both Butt fusion and electrofusion pipe welds. We can offer a fully managed solutions to pipeline integrity testing drawing on our knowledge and expertise in pipes and pipeline materials. Contact us today for a free consultation.

Be sure to follow us on Twitter, Facebook and LinkedIn to learn more!