Biodisintegration EDANA FG505/506 R1 (Part A) – Testing Flushable Products

Industry standards have been developed to simulate the conditions found in sewerage and wastewater treatment systems and specify acceptable time frames and the degree of disintegration products must comply with in order to be marketed as flushable. This includes both aerobic and anaerobic conditions to mimic different parts of the process and ensure the product is capable of breaking down in either scenario.

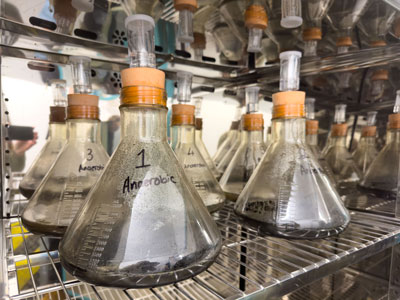

Part A biodisintegration testing involves the incubation of a sample in a biologically active solution taken directly from a wastewater treatment facility. Steps are taken in handling, transfer, and storage of samples and reaction vessels during testing to ensure solutions are continually aerated in the case of aerobic testing or kept under a blanket of nitrogen to maintain anaerobic conditions. Reaction vessels are also closely temperature-controlled, depending on the requirements of the standard being tested. After the specified time period has elapsed, the contents of the vessels are passed through fine mesh sieves so that any breakdown fragments larger than the pass criteria are retained. The retained material is weighed, allowing the degree of disintegration of the product to be ascertained.

Either of these biodisintegration tests (EDANA FG505.R1 and FG506.R1) can be used to assess the potential for a disposable nonwoven material to biologically degrade under anaerobic and aerobic conditions typically found in sewers as well as on site and municipal wastewater treatment systems.

Part B biodegradation testing requires the OECD 301 method and is a standardised biodegradation test that measures the evolution of carbon dioxide or methane resulting from the mineralisation of the organic constituents of the sample.