Lithium Ion Battery Failures

Types of Lithium battery failures

Lithium-based batteries and cells have become more integrated in our everyday lives, from consumer products like mobile phones to the more demanded electric vehicles (EV). We know that lithium-based batteries such as lithium-metal or lithium-ion are safe to use. As with any energy storage devices, they still carry risks and with the millions of lithium-based batteries produced, battery failures are inevitable. Nevertheless, battery manufacturers continue to strive for battery reliability including battery safety as well as battery performance. Battery manufacturers are obligated to fulfil safety requirements and Li-ion batteries have a failure rate of less than one in a million, in fact high quality Li-ion batteries have a further reduced failure rate.

In general, the root causes of battery failures are categorised into the following:

- Thermal abuse

- Electrical abuse

- Mechanical abuse

- Manufacturing defects leading to internal cell faults

- Poor cell electrochemical design

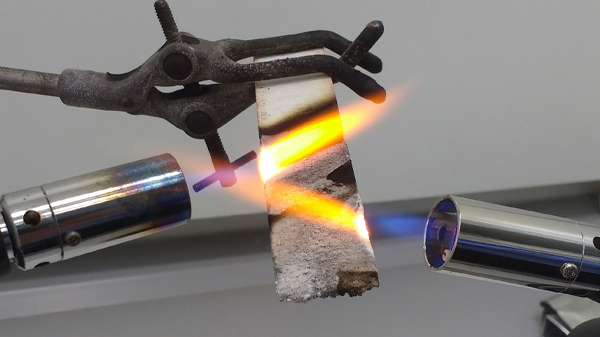

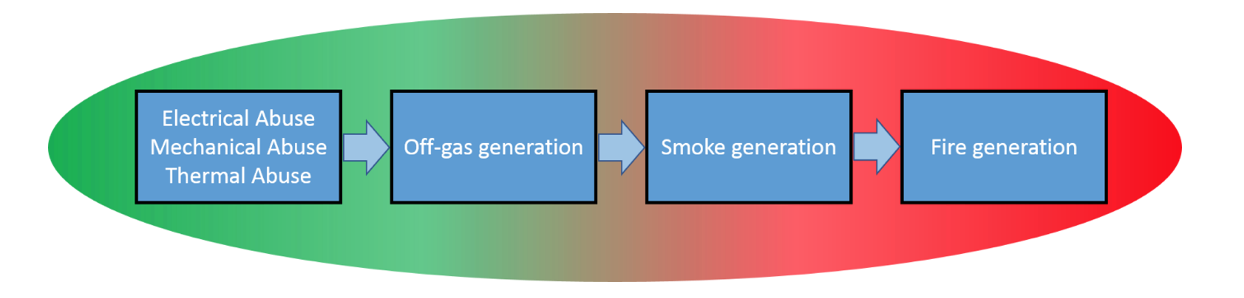

The aforementioned failure modes of batteries will lead to the following consequences, which are the typical stages of Li-ion battery failure:

Stage 1: Initial abuse factor (described from above)

Stage 2: Swelling and Venting of cell

Stage 3: Smoke generation

Stage 4: Thermal runaway

A battery management system (BMS) is typically capable of detecting the stages of failure of a cell. A BMS aims to monitor the physical characteristics of the individual lithium-ion cell. However, the length of time between detecting stage 1 and stage 2 this is highly dependent on the type of abuse imposed on the cell. This is because, in the case of mechanical abuse, for example a direct penetration into the cell, the internal structure of the cell is immediately compromised and exposed, therefore there will be no time between stage 1 and stage 2. On the other hand, in cases such as electrical abuse, from the initiation of the abuse to the swelling then venting of cell can be observed to occur from 30 minutes to several hours. Nevertheless, this length of time is also influenced by the intensity of the abuse as well as the energy factor of the cell.

Once stage 2 has been initiated and gas has been generated, there is no mitigation action required because the battery has already failed and the failure will continue to progress. Stage 3 which is the generation of smoke already indicates that the cell has reached a critical point of failure and thermal runaway in underway. At stage 3 where smoke has been generated, the Li-ion cell is very unstable and it is typical that the battery will be inferno next. This is because the cell is in a fully developed thermal runaway and is capable of producing its own heat and energy. The Li-ion cells contain electrodes with metal oxide, during decomposition the cell can generate its own oxygen supply and fuel the blaze. For an individual cell that entered thermal runaway may seem controllable, however, in cases where cells are delivered in a pack or in devices with multiple cells, the consequences become catastrophic. One of the main concerns around Li-ion battery shipments is, even if one individual cell enters thermal runaway, it is very likely to propagate its failure and spread heat to its surrounding cells. For this reason, Li-ion battery safety should have a very proactive approach to reduces failure rates, prevent thermal runaway propagation using appropriate packaging and mitigate catastrophic events by using prognostic early warning technologies.

Impact solutions plays an active role in contribution towards these proactive strategies by being a part of two separate projects which ultimately aims to enhance the safety and performance of lithium-based batteries. Project Sabatair is established by the European Commission and the European Union Aviation Safety Agency (EASA).