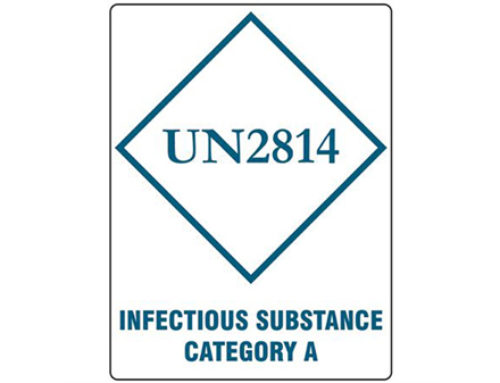

It is important to pressure test medical appliances and equipment. A manufacturer of medical tubes approached Impact Solutions, asking for us to test their packaging for signs of leakage. We tested the tubes under 95kPa pressure differential testing, to UN regulations for air transportation.

While in transit, medical tubes such as vaccines, can leak due to pressure and temperature changes. This has recently been an issue that required an aircraft evacuation at Glasgow Airport and caused for the immediate area to be sealed off after the vaccines leaked in the cargo hold of a plane. Such leaks can cause all kinds of problems, and as you will appreciate, especially when in midair and in the cargo hold of an aeroplane.

For testing, the tubes were filled with a transparent solution and sealed and tested as supplied. The tubes were weighed to the nearest 1mg, then placed in a desiccator. A blue paper cloth was placed underneath the samples to detect any leaks. The desiccator was moved to an environmental chamber, to maintain the required temperatures. Tested at different temperatures for 2 hours and a vacuum applied to create 95kPa pressure differential for a further 30mins and then visually inspected for any signs of leakage. No leaks were detected.

Immediately after the visual inspection, the samples were placed back in the chamber which was set at a temperature of +55℃ and allowed to condition for 2 hours, followed by vacuum for 30mins. The samples were then visually inspected again to detect any signs of leaks.

When the tests had been completed, the tubes were weighed and results were compared to starting weights. There was no change in mass.

This is an exceedingly important thing to test. Impact Solutions are able to test medical devices and equipment under 95kPa pressure differential testing requirements. If you are interested in this test, contact us today!

Be sure to also follow us on Facebook, LinkedIn and Twitter in order to stay up-to-date with our testing capabilities.