A way that we traditionally use to save resources, such as raw material, water and energy, is recycling. Here we are looking at the characterisation of recycled PE (polyethylene) through the European standard BS EN 15344.

The environmental impacts of recycling have a lot of consideration and assessment before going through the recycling process. The recycling process has to have a lesser environmental impact than other alternatives. Collection schemes have to be designed to properly to know which materials can be compatible with the current recycling technologies available. European standard BS EN 15344 lays out test methods and characteristics for PE recyclate that will be used in either semi-finished or finished products.

How do recyclers characterise recycled PE to BS EN 15344?

PE will be charaterised by different batches. The required characteristics are required for all recyclates, detailing:

- Bulk density

- Colour

- Particle size

- Melt mass flow rate (MFR)

The optional characteristics, which can provide a little more information on the material:

- Ash content

- Density

- Contaminants

- Filtration level

- IZOD impact strength OR charpy impact strength

- Residual humidity

- Tensile stress at yield

- Tensile strain at break

Method for the determination of contaminants

This details the contaminants that may be found and determining them visually. There are three methods that can be used for determining whether there are non-melted particles and impurities (contaminants) in reyclate. Batches of granules will be extruded at a weight of 10kg and will then be visually inspected to determine contaminants.

Test method for the determination of bulk density

Bulk density refers to the mass per unit of volume relative to granules or a powdered material. This would be useful information to have in regards to give an idea on how stable mixing will occur, effects of humidity and consistency between batches.

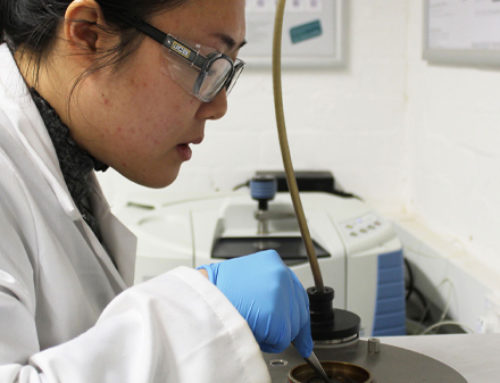

At Impact, our experts have the knowledge and equipment required to carry out these tests for recyclers to give additional information regarding their material. For more information, contact one of our experts or call us today at +44 1324 489 182.

Be sure to also follow our Facebook, LinkedIn and Twitter to learn more about our testing capabilities.